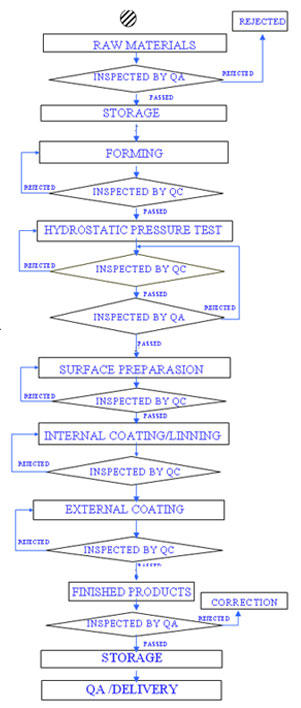

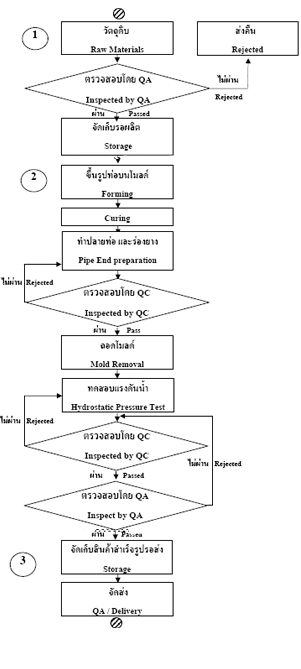

Production Process From Rolling to Coating Steel pipes are made from either steel plates or coils : Steel Plate / Steel Coil Pipe Forming Inside Welding (by an automatic submerged arc welding process) Outside Welding (by an automatic submerged arc welding process) Pipe End Preparation Ultrasonic/X-Ray Testing Hydro static Testing Surface Preparation Inside Coating Outside Coating Final Inspection of End-Product |

| INSPECTION ITEM | INSPECTION & TEASTING |

| 1. RAW MATERIAL STEEL PLATE AND COIL |

- ULTRASONIC THINCKNESS GAUGE - VERNIER CALIPER STEEL TAPE |

| 2. FORMONG & - HYROSTATIC PRESURE TEST - RADIOGRAPHIC INSPECTION (X-ray) |

- VERNIER CALIPER STEEL TAPE - MULTI-WELDING GAUGE - HYDROSTATIC TEST MACHINE - SMART 200 X-RAY UNIT (60-220Kva Thk 1-49 mm) |

| 3. SURFACE PREPARATION & COATING | - ADHESIN TESTER - VERNIER CALIPER - SA2.5 FILM STANDARD - ELECTROMAGNETIC THICKNESS GAUGE - WET FILM THICKNESS GAUGE - HOLIDAY DETECTOR (ELCOMETER) |

| 4. PRODUCT FINAL INSPECTION | - VERNIER CALIPER STEEL TAPE - ELECTROMAGNETIC THICKNESS GAUGE - HOLIDAY DETECTOR |