|

|

Require ments for the design The followings are requirements for the design of the Expansion Joint. These requirements shall be fulfilled through your inquiry. |

| 1. Pipe size | Nominal diameter of pip |

| 2. Standard of pipe, wall thickness, maerial |

Standard of pipe(AWWA, BS, API etc.), schedule no, in the case of non-standardized pipe, outside(or inside) diameter, wall thickness, material, |

| 3. Connection |

Beveling configuration(distinction between internal and external, angle, etc.) in welding, standards, dimention, material, etc., in flange connection, and particular standards(ISO, ANSI etc.) |

| 4. fluid | Needed for selecting the material for bellows. |

| 5. Pressure | Needed for selection of type |

| 6. Temperature | Need for selecting the material and type of bellows. |

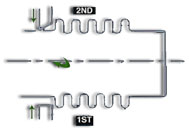

| 7. Movement and direction |

Needed of selectiong the number of corrugations, single and double. If these data are not manifest, contact us with respect to pipe length (distance between the fixing points) and temperature. (We will calculate them) |

| 8. Material for bellows |

We select the most suitale, depending upon the fluid, temperature and pressure. However , examine and enter the temperature of fluid, the property of material, etc., if you particularly to specify. |

| 9. Presence of inspection by authorities concerned and in attendance thereot |

Always enter the necessity of inspection in the attendance of the Authority or Third-Party inspection. Further, enter also the necessity of specific inspection, X-ray, liquid penetrant etc. |

| 10. Equation to be used in caicuation |

Generally, we carry out the caiculation based upon the equation derived from EJMA and the experimental value. If you particularly specify the number of expansion cycles, enter that specification. |

| 11. Oters |

Consult with us about the use of Expansion joint when it is used in a special almosphere, when the fixing point are not provided, etc. We will assist you in the examination of pipe line. The selection of material and type, the calculation of load in the fixing points, etc. |

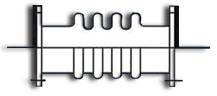

| Expansion Joints Fabrication procedure |

|

|

|

|

||

| Cutting of the thin bellows layers |

|

Rolling on roller bending machine | Welding of the outer and inner layer Radiography & Liquid Penetrated test | |

| ........................................................................................................................................... |

||||

|

|

|

||

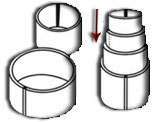

| Polishing | Preparation of the and welded inner and outer layer | Multiply bellows | ||

| ........................................................................................................................................... |

||||

|

|

|

||

| Roll forming by wheel or hydraulic powered forming | Multiply expension bellows alter forming | Edge Cutting | ||

| ........................................................................................................................................... |

||||

|

||||

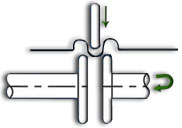

| Weld attachment to the shell or fittings | ||||